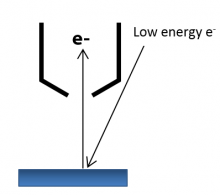

Electron energy loss spectroscopy (EELS) involves the exposure of the sample to a focused beam of monoenergetic electrons, typically < 2keV. As these electrons interact with the material some of them will undergo inelastic scattering whereby they lose some kinetic energy. In reflection electron energy loss (REELS) the electrons that are both eleatically and inelastically scattered are collected using the AXIS electron energy analyser. The low-energy electron energy loss spectrum (up to ~50eV in energy loss) contains the elastic, or zero-loss, peak as well as the plasmon peaks. This spectrum can be used to determine information about the band structure and dielectric properties of the sample.

The high energy-loss region, generally accepted as >50 eV, contains the ionisation edges due to inner shell ionisations. It is these features which are the exact equivalent of an absorption edge in XAS, arising from the same process. They are characteristic of the elements present in the sample and their local bonding environment, providing the atomic and chemical bonding information.

Calculated sampling depth for a 1 keV REELS experiment is ca. 15 nm, although it is noted that this will be dependent on the material being analysed and the energy of the primary electron beam. Information from the REEL spectrum is therefore complementary to other surface sensitive techniques, including XPS.

Information content from REELS experiments

- Probe surface valence and conduction band electronic properties.

- Band gap determination for semiconductor materials.

- Comparison of relative hydrogen content in polymer materials.

- Investigation of conjugation or aromaticity in organic materials.

- Determination of sp2 / sp3 hybridisation of carbon

Where the AXIS Supra+ is configured with the 10 keV FE-electron source for Auger electron spectroscopy, REELS can be added as an additional capbility. Alternatively an optional static electron source can be added to provide the REELS capability. Further details of the REELS accessory can be found in Technical Note MO466.